3D Printing with Mycelium using a Sodium Alginate scaffold

In this final project for How To Grow (Almost) Anything, I propose an experimental setup that demonstrates the potential of a 3D printed alginate hydrogel with mycelium and present a theoretical overview of current applications of SynBio in architectural contexts.

It combines concepts from the following classes:

-

3D Bioprinting (silk fibroin extraction protocol)

-

Hardware (the syringe pump extruder can be used to 3D print)

Introduction

The fabrication of Mycelium-based building blocks

The experiment is divided in two parts: 1) 3D printing with alginate and 2) to test if mycelium can grow in alginate gels.

Materials and Equipment

-

Sodium Alginate (Sigma-Aldrich)

-

Gelatin from porcine skin (Sigma-Aldrich)

-

Food coloring

-

Calcium Chloride (Sigma-Aldrich)

-

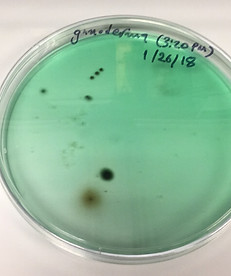

Ganoderium

Protocol

-

Make a 2% (wt/vol) Sodium Alginate solution, by mixing the powder in a beaker with deionized water

-

Add food coloring to be able to differentiate the alginate from the calcium chloride

-

Place the solution on a hot stirring plate for 5-10 min, stir manually

-

In a separate beaker, make a 1-5% Calcium Chloride or Calcium Acetate Gluconate solution

(1.5%-2.5% CaCl2 will be good for better stability and permeability of the gel) -

Experiment 1: 3D printing

The sodium alginate-gelatin structure was printed in

An experiment was set up to determine whether it is possible to 3D print with Sodium Alginate, if it were to be extruded in a three dimensional structure. The alginate-gelatin solution displayed below was 3D printed at the Stevens Institute of Technology, and proves that alginate can be used as a structural building material. Further iterations with variations in material composition, geometry can be carried out to optimize this material.

Experiment 2: Mycelium growth

The objective of the second experiment is to find out if it is possible to grow mycelium in alginate gels.

[reference to literature on alginate-mycelium symbiosis]

Conclusions and Further Directions

The results of experiment 2 indicate that it is possible to grow mycelium in alginate hydrogels. Areas of concern/improvements are:

-

Find ways to reduce dehydration

-

Height of 3D printing (structure collapses)

-

CaCl2 + mycelium, not the best combination

-

Processing: CaCL2 bath not the most optimum in large scale applications

-

Find a way to prevent mold growth in the gel. Sterile environment

Theoretical framework

The construction materials we use are often contain high embodied energy and toxicity. Within our current linear economy, fossil fuels are used in the entire production process, from extraction of raw materials to disposal. Building with engineered biological materials might provide a healthier and cleaner alternative for construction and simultaneously make our living spaces responsive to its environment and our bodies. Can we work with synthetic biology make carbon neutral building materials? Would it be possible to have building materials that act as living sensors?

by BioMASON

by Delft University of Technology

Feature

-

Self-healing

-

Detect and respond to hazardous particles

-

Improve indoor quality

-

Light production

-

Temperature sensor and control

-

Earthquake detector

-

Energy generation

-

Food production

-

Carbon sequestration

Example

-

Encapsulated bacteria that excrete CaCO3 when cracks appear

-

Biosensors that filter out specific particles and change color when saturated

-

Bio-active surfaces that secrete beneficial bacteria

-

By bioluminescent bacteria or algae

-

RNA thermometer

-

Bio-sensor that responds to vibrations

-

With algae or microbial fuel cells (MFC) in micro- or macrofluidic channels

-

Embed seeds or algae in hydrogel